your blueprint to success

Welcome to Optimised 3D Engineering

We offer full-scope design-to-manufacturing solutions that bring our clients ideas, inventions and concepts to life. We do not see ourselves as merely engineers or designers, but as problem-solvers first and foremost.

Our clients do not just benefit from our attention to detail and high manufacturing ceiling – They benefit from our dedication to a fully bespoke service on a first-name basis that resembles a partnership more than a typical B2B arrangement.

Looking for flexible engineering and manufacturing solutions? Book a 30-minute consultation with one our team below.

Bespoke Digital Manufacturing

Establish a flexible and cost-effective manufacturing base for your products.

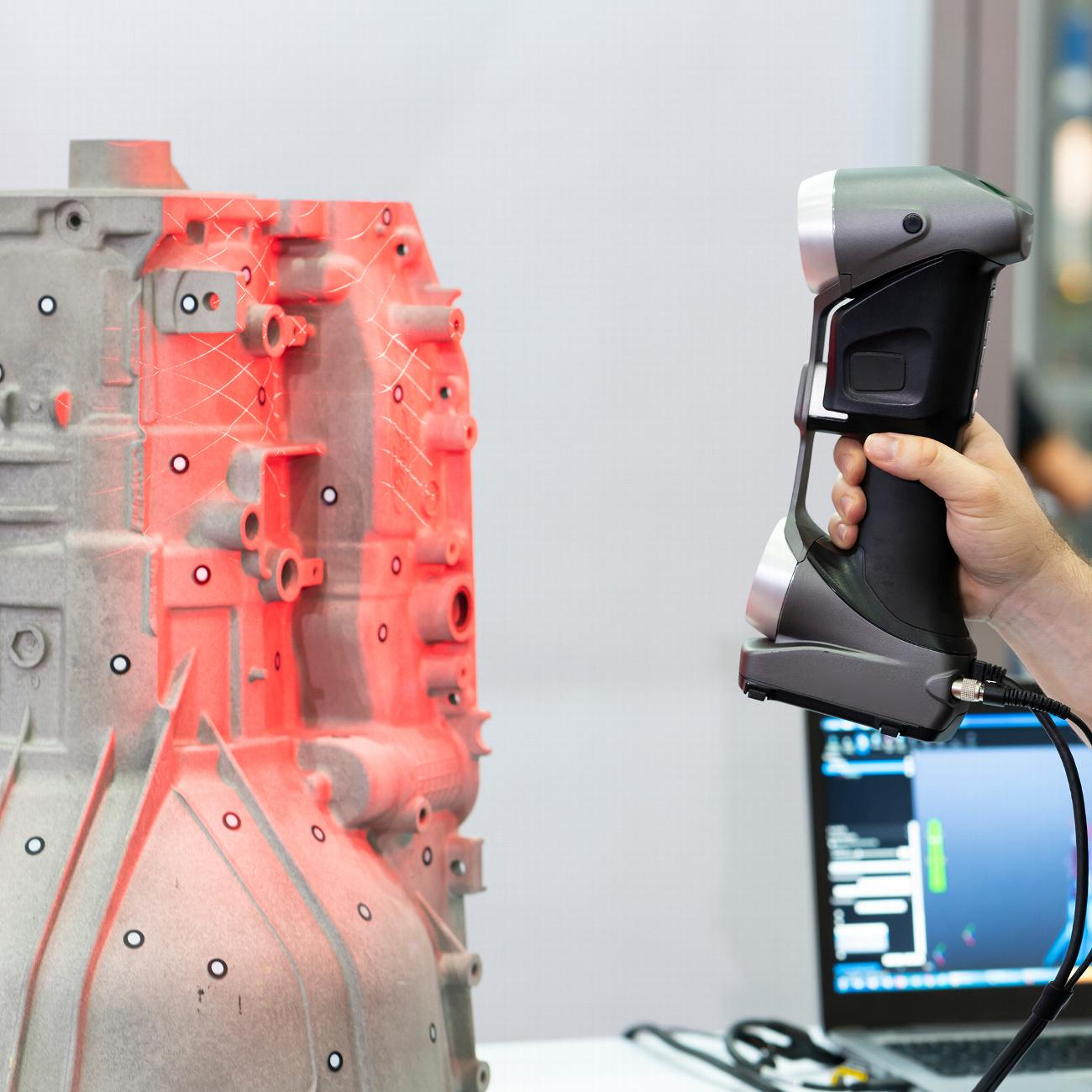

Reverse-Engineering & Design Refinement

Replicate or refine an existing product with the latest in 3D scanning technology.

Our Digital Manufacturing Services

Contact Us

Each of these services are fully flexible and can be tailored to your needs. Find out more about how we can help by calling the team at 0800 861 1701.

Some Of Our Past Clients

"I went to Optimised 3D with a very rough product idea, they came up with some really great designs and completely thought outside the box. I got the prototype and I love it. Peter kept me in the loop the entire time and was so helpful if I had any questions. I'll be in touch soon to order the first batch. Thank you."

Jasmine Summers

"First time I have approached Peter and the team was a while back and I was trying to describe to him what I wanted, but wasn't very sure how it should look like etc. Peter took a long time on the phone with me and he was very kind to take all notes and he called me back with all his research and it was perfect! I cannot recommend his company enough. The whole team is absolutely fantastic and I am looking forward to my launching and future collaboration. Only wish all businesses will be as honest and this one. I will 10000% recommend them."

Beauty by Mirka

Frequently Asked Questions

How much are your services?

We offer our clients a fully flexible pricing model instead of more rigid productised services. A simpler project will have a lower price, while a more complicated or larger-scale project will have a correspondingly higher price.

Where do you offer your services?

Though we principally work with British customers, Optimised 3D Engineering can and do offer our services all around the world.

Do your clients get involved?

Yes – As part of our flexible approach, we are to involve our clients as much or as little as they would prefer. Some customers prefer to oversee their project with occasional check-ins, while others desire to be involved every step of the way from the initial designs to the final mock-ups.

We can tailor our approach according to your preferences, but we find that the more involved a customer is, the more satisfied they are with the final product.

Is my intellectual property safe with you?

Yes – Optimised 3D Engineering as an entity is based in the UK. We therefore adhere to and operate under strict European laws and standards when it comes to legal and intellectual properties.

I need some prototypes as soon as possible, can you help?

We certainly can. A benefit of our unique digital manufacturing services is our ability to tailor the speed of our services to fit around even tight budgets and timescales.

Do you have any size or order quantity minimums?

No – We are more than happy to work with clients for one-off projects, should they need a particular component or product reverse-engineered, and treat these with the same level of care and attention to detail as we would our larger contracts.

What are the advantages of digital manufacturing?

There is a plethora of advantages to digital manufacturing, which in many ways represents a revolution in the manufacturing and engineering industry. These include:

- Faster production times, leveraging technologies like 3D printing for complex parts

- Customisation and personalisation, based on individual preferences and requirements

- Cost efficiency, via optimising designs, reducing waste and enabling on-demand production

- Decentralised production, reducing dependence on centralised factories and vulnerable supply chains

- Rapid prototyping and iteration, speeding up the product development process and improving the final product

Optimised 3D Engineering are a bespoke provider of end-to-end design, engineering and manufacturing solutions.

Why choose Optimised 3D engineering?

Our Flexible and Honest Approach

We offer our clients a tailorable balance between price, speed and quality. Whether you need a large number of simple goods on short notice, a handful of high-quality products on a small budget or something else, our digital manufacturing services fit around your specific situation and needs.

The Best of British Services at a high capacity

Optimised 3D Engineering takes advantage of the global market by basing our quality control systems and processes in the United Kingdom while having an international manufacturing base.

This gives you the quality you would expect of UK-made goods at a far higher manufacturing ceiling and speed.

Our Dedication to a Bespoke Service

As a smaller provider of digital manufacturing services, Optimised 3D Engineering are uniquely positioned to offer a bespoke one-to-one service. We endeavour to get to know each client on a first-name basis and the intricacies of their project inside-and-out.

Your business is unique, and so should be your engineering solutions. Learn more about how we can create a custom solution for you by booking a 30-minute consultation. For general enquiries, please call us at 0800 861 1701.

Optimised 3D Engineering are a bespoke provider of end-to-end design, engineering and manufacturing solutions.

Looking to find out more about our services? Get in contact with us at contact@optimised3d.com or call us directly at 0800 861 1701.